Blog

Conveyor vs Undercounter Dishwasher for Your Restaurant?

Introduction: Making the Right Dishwasher Choice for Restaurant Efficiency

Every successful restaurant depends on fast, reliable, and hygienic dishwashing. When it comes to selecting equipment that keeps up with service speed and cleanliness standards, operators often face a critical decision: Should you invest in a conveyor vs undercounter dishwasher setup?

This comprehensive guide answers that question head-on by exploring pros, cons, capacity planning, operational requirements, and real-world tips for choosing the right commercial dishwasher. Whether you operate a cozy café or a high-volume kitchen, understanding the differences between conveyor vs undercounter dishwasher systems will help you reduce labor costs, improve hygiene, and streamline back-of-house workflows.

What Is a Conveyor Dishwasher? (Conveyor vs Undercounter Dishwasher Overview)

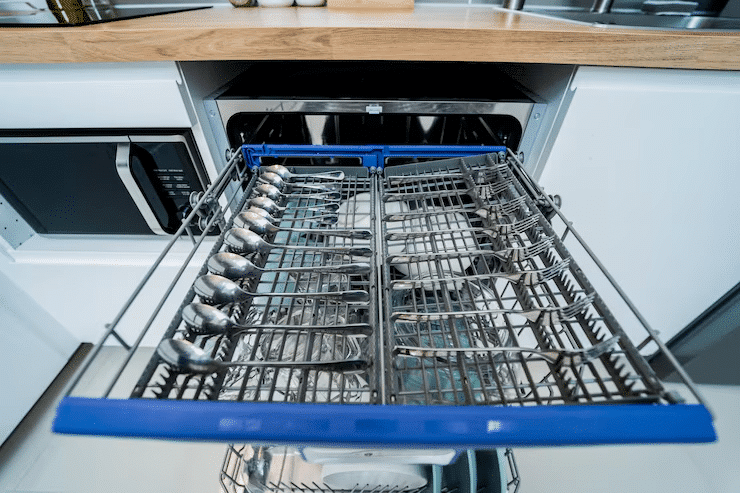

A conveyor dishwasher is a large, high-throughput machine designed to handle continuous dishwashing. Plates, glasses, and utensils are placed on racks that move through a conveyor system, getting cleaned, sanitized, and dried in one continuous cycle.

Key Characteristics

- Designed for high volumes (often 250+ racks/hour)

- Operates continuously during peak periods

- Larger footprint, usually requires dedicated space

In the conveyor vs undercounter dishwasher comparison, conveyor systems shine in environments where speed and capacity are paramount.

read more : restaurant dishwasher equipment UAE : Hygiene & Capacity Guide

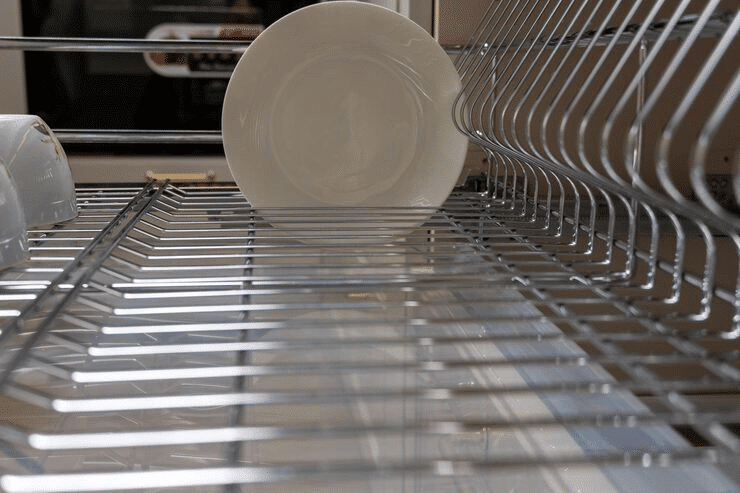

What Is an Undercounter Dishwasher? (Conveyor vs Undercounter Dishwasher Explained)

An undercounter dishwasher is a compact, space-saving machine installed beneath a countertop. These units are common in smaller restaurants and cafés.

Key Characteristics

- Ideal for small to medium plate volumes

- Compact and easy to install

- Lower upfront cost than conveyor systems

In the conveyor vs undercounter dishwasher matchup, undercounter units excel in tight spaces where service speed is moderate and countertop workflow is critical.

Capacity: Throughput Comparison (Conveyor vs Undercounter Dishwasher)

Effective capacity planning helps you avoid bottlenecks and overcapacity.

| Feature | Conveyor Dishwasher | Undercounter Dishwasher |

| Typical throughput | 250–1200+ racks/hour | 20–60 racks/hour |

| Best suited for | High-volume kitchens | Small to medium restaurants |

| Peak service performance | Excellent | Moderate |

| Ideal usage | Continuous dish cleaning | Small service cycles |

This capacity contrast is a central factor in the conveyor vs undercounter dishwasher evaluation—especially when planning around peak lunch or dinner rushes.

Space & Layout Requirements (Conveyor vs Undercounter Dishwasher)

Space is often one of the biggest limitations in restaurant kitchens.

Conveyor Dishwasher Considerations

- Requires significant floor space

- Needs clear entry and exit points for racks

- Often paired with dish tables and racks nearby

Undercounter Dishwasher Considerations

- Fits under existing counters

- Minimal dedicated floor space required

- Ideal for small kitchens and bar areas

In the conveyor vs undercounter dishwasher debate, undercounter units deliver a big advantage where space is tight, while conveyors demand dedicated planning.

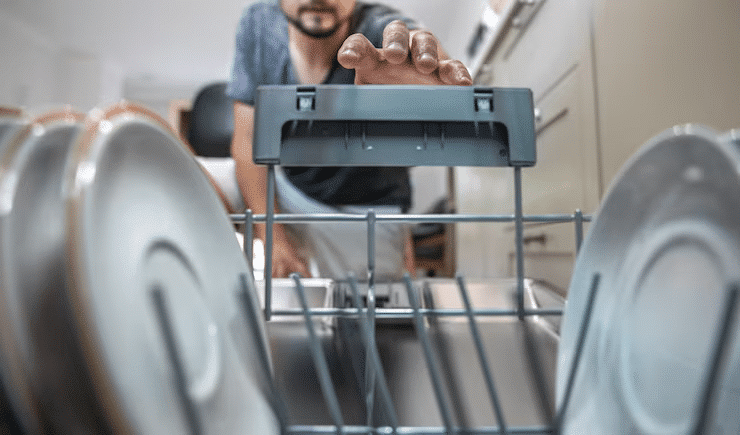

Hygiene & Performance (Conveyor vs Undercounter Dishwasher)

Both systems aim to deliver hygienically clean dishware that meets health code standards.

Conveyor Dishwasher Benefits

- Automated cycles with higher temperature sanitization

- Consistent cleaning for large batches

- Fewer manual handling errors

Undercounter Dishwasher Benefits

- Quick cycles for smaller batches

- Convenient location near service lines

- Lower water and chemical usage

If hygiene and consistency under heavy loads are top priorities, conveyor systems often outperform undercounter counterparts in the conveyor vs undercounter dishwasher category—especially under peak service.

Energy, Water Use & Operating Costs (Conveyor vs Undercounter Dishwasher)

Cost of operation includes utilities, chemicals, and labor.

Conveyor Systems

- Higher water and energy use

- Higher overall throughput reduces per-dish cost

- Often equipped with heat recovery and savings features

Undercounter Systems

- Lower energy and water consumption per cycle

- Lower overall operating cost for small volumes

- Limited capacity may require more labor

In the conveyor vs undercounter dishwasher comparison, cost efficiency varies based on your service volume and usage pattern.

Installation & Ventilation Requirements (Conveyor vs Undercounter Dishwasher)

Conveyor systems require careful planning and infrastructure.

Conveyor Dishwasher Needs

- Dedicated drainage

- High-temperature sanitizing water supply

- Ventilation hoods for steam management

Undercounter Dishwasher Needs

- Standard drain and water hookups

- Typically no special ventilation

If installation simplicity matters, undercounter units often win the conveyor vs undercounter dishwasher battle.

Maintenance & Longevity (Conveyor vs Undercounter Dishwasher)

Routine maintenance protects performance and prevents downtime.

Conveyor Dishwasher Pros

- Designed for heavy use with replaceable parts

- Service contracts often available

Undercounter Dishwasher Pros

- Easier to access components

- Lower maintenance cost overall

Both systems benefit from regular cleaning of wash arms, filters, and racks to maintain performance and hygiene.

Cost Comparison & ROI (Conveyor vs Undercounter Dishwasher)

Upfront Costs

- Conveyor systems: Higher purchase and installation costs

- Undercounter systems: Lower initial investment

Return on Investment

- Conveyor systems: Fast payback in high-volume kitchens

- Undercounter: Cost-effective for smaller operations

In conveyor vs undercounter dishwasher decisions, your expected dishwash volume dramatically influences ROI.

Best Use Cases (Conveyor vs Undercounter Dishwasher)

- Busy full-service restaurants: Conveyor dishwasher for steady service flow

- Cafés, bars, and small diners: Undercounter dishwasher for compact efficiency

- Banquet halls and hotels: Conveyor systems paired with rack stations

- Pop-ups and food trucks: Space-saving undercounter units

Matching equipment to real usage scenarios helps you decide between conveyor vs undercounter dishwasher solutions that fit your model.

Common Mistakes When Choosing Dishwashers for Restaurants

Avoid the following pitfalls:

- Assuming all dishwashers are “one size fits all”

- Ignoring peak service capacity needs

- Overlooking installation and ventilation requirements

- Choosing based only on price

Each mistake can undermine your operations and magnify the impacts of the conveyor vs undercounter dishwasher choice.

Conclusion: Choosing Between Conveyor vs Undercounter Dishwasher

Deciding between a conveyor vs undercounter dishwasher comes down to your restaurant’s size, service volume, kitchen space, and efficiency goals. Conveyor systems excel at high capacity and continuous throughput, making them ideal for busy restaurants and banquet facilities. Undercounter dishwashers, on the other hand, offer compact convenience for cafés, bars, and small to medium restaurants.

Evaluate your dish volume, peak times, staffing, and budget carefully. With the right choice, you’ll streamline back-of-house workflows, enhance hygiene compliance, and support smoother service every day.

👉 If this guide helped you, share it with fellow restaurant operators, explore our related kitchen equipment resources, or leave your questions in the comments—we’re here to help you make smarter dishwasher decisions.

Improve hygiene while reducing labor and operating costs.

Speak with our specialists to choose dishwasher equipment designed for your restaurant’s workload and efficiency goals.

Commercial Cooking Heaters

Commercial Cooking Heaters